Tangent Ogive vs. Secant Ogive: Understanding Composite Propellant Grain Design

In the realm of rocket propulsion and solid propellant grain design, the terms tangent ogive and secant ogive often arise. These terms describe specific geometric profiles used in the design of the forward end of a solid rocket motor’s grain. Understanding the nuances between a tangent ogive and a secant ogive is crucial for engineers aiming to optimize motor performance, ensure structural integrity, and achieve desired thrust profiles. This article delves into the definitions, characteristics, applications, and comparisons of these two ogive types, providing a comprehensive overview for both seasoned professionals and newcomers to the field.

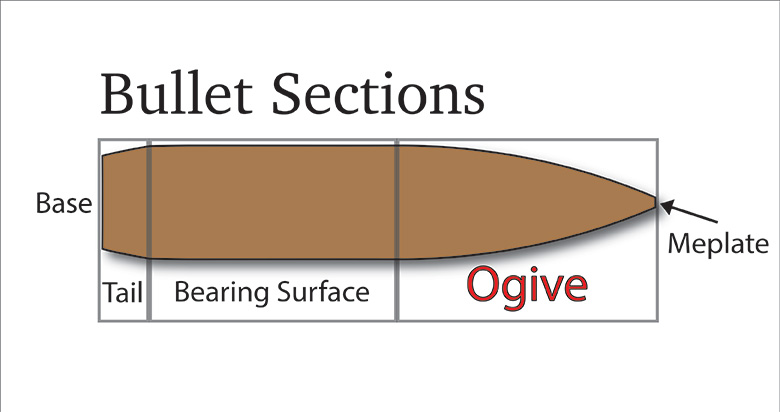

Defining Ogive Geometry

Before diving into the specifics of tangent ogive and secant ogive shapes, it’s essential to understand the fundamental definition of an ogive. An ogive is a curved shape formed by two arcs that are tangent to each other. In the context of propellant grain design, the ogive typically refers to the curved forward end of the grain, designed to provide a smooth transition from the cylindrical section to the igniter port or a converging nozzle.

Tangent Ogive: A Smooth Transition

A tangent ogive is characterized by its arc being tangent to the cylindrical portion of the grain at the point where the ogive begins. This tangency ensures a smooth and continuous transition, minimizing stress concentrations and promoting uniform burning. The radius of the ogive arc is a key design parameter, influencing the overall shape and performance of the grain. The key advantage of using a tangent ogive is the smooth transition it provides which can prevent cracking or stress concentrations in the propellant. By carefully selecting the radius of the tangent ogive, engineers can fine-tune the initial burning surface area and, consequently, the initial thrust of the motor.

Characteristics of Tangent Ogive

- Smooth transition from cylindrical section

- Arc tangent to the cylindrical section

- Minimized stress concentrations

- Uniform burning characteristics

Applications of Tangent Ogive

Tangent ogives are commonly used in solid rocket motors where a gradual increase in burning surface area is desired at the start of combustion. This can be beneficial for achieving a stable and controlled ignition process. They are often favored in applications where minimizing stress within the propellant grain is a primary concern, such as in larger motors or those subjected to high acceleration loads. The predictable burning characteristics associated with a tangent ogive make it a popular choice in many rocket designs.

Secant Ogive: A More Aggressive Profile

In contrast to the tangent ogive, a secant ogive is defined by its arc intersecting the cylindrical portion of the grain. This intersection creates a more abrupt transition, resulting in a sharper curvature at the forward end of the grain. While this design can lead to increased stress concentrations, it also offers the advantage of a larger initial burning surface area. The secant ogive is often chosen when a rapid increase in thrust is required at the beginning of the motor’s operation.

Characteristics of Secant Ogive

- Abrupt transition from cylindrical section

- Arc intersects the cylindrical section

- Potentially higher stress concentrations

- Larger initial burning surface area

Applications of Secant Ogive

Secant ogives are frequently employed in applications where a high initial thrust is critical, such as in missile systems or booster stages. The increased burning surface area at ignition allows for a faster pressure buildup and a more aggressive initial acceleration. However, the higher stress concentrations associated with a secant ogive necessitate careful design considerations to ensure the structural integrity of the propellant grain. [See also: Composite Propellant Formulation]. The design needs to account for the increased stress. Using a secant ogive can be beneficial in situations that require rapid acceleration.

Tangent Ogive vs. Secant Ogive: A Detailed Comparison

The key difference between a tangent ogive and a secant ogive lies in the nature of their transition from the cylindrical section of the grain. A tangent ogive provides a smooth, continuous transition, minimizing stress concentrations and promoting uniform burning. A secant ogive, on the other hand, offers a more abrupt transition, resulting in a larger initial burning surface area but also potentially higher stress levels. The choice between these two ogive types depends on the specific performance requirements and design constraints of the solid rocket motor.

Stress Considerations

Stress analysis is a critical aspect of propellant grain design, particularly when using a secant ogive. The abrupt transition in a secant ogive can create localized stress concentrations that may lead to cracking or other structural failures. Finite element analysis (FEA) is often employed to simulate the stress distribution within the grain and identify areas of potential weakness. Mitigation strategies, such as incorporating stress-relieving features or using higher-strength propellant formulations, may be necessary to ensure the reliability of the motor.

Burning Rate and Thrust Profile

The ogive geometry significantly influences the burning rate and thrust profile of the solid rocket motor. A tangent ogive typically results in a more gradual increase in thrust over time, while a secant ogive can provide a more rapid initial thrust spike. Engineers carefully tailor the ogive shape to achieve the desired thrust characteristics for a given mission profile. Computer simulations and experimental testing are used to validate the predicted burning behavior and thrust output.

Design Parameters

Several key design parameters are associated with both tangent ogive and secant ogive geometries. These include the ogive radius, the transition point, and the overall length of the ogive section. Optimizing these parameters is crucial for achieving the desired performance characteristics while maintaining structural integrity. Iterative design processes, combined with computational modeling and experimental validation, are often employed to arrive at the optimal ogive design. Choosing the correct design parameters for a tangent ogive or a secant ogive is crucial for achieving the desired performance.

Advanced Considerations

Beyond the basic definitions and comparisons, several advanced considerations come into play when selecting and designing ogive geometries for solid rocket motors.

Hybrid Ogive Designs

In some cases, hybrid ogive designs may be employed to combine the advantages of both tangent ogive and secant ogive profiles. For example, a design might incorporate a short secant ogive section to provide an initial thrust boost, followed by a tangent ogive section to ensure a smoother and more controlled burn. These hybrid approaches require careful analysis and optimization to ensure that the transition between the two ogive sections is smooth and does not introduce undue stress concentrations.

Ogive Effects on Motor Stability

The ogive geometry can also influence the overall stability of the solid rocket motor. Aerodynamic forces acting on the forward end of the motor can be affected by the shape of the ogive, potentially leading to instability during flight. Computational fluid dynamics (CFD) simulations are often used to analyze the aerodynamic characteristics of different ogive designs and ensure that the motor remains stable throughout its operational envelope.

Manufacturing Considerations

The manufacturability of the ogive shape is another important consideration. Complex ogive geometries may be difficult or expensive to manufacture using traditional molding techniques. Additive manufacturing (3D printing) technologies are increasingly being used to create intricate ogive shapes with greater precision and design flexibility. The tangent ogive and secant ogive both have manufacturing considerations that should be taken into account during the design process.

Conclusion

The choice between a tangent ogive and a secant ogive in solid rocket motor design is a critical decision that significantly impacts motor performance, structural integrity, and overall mission success. A tangent ogive offers a smooth transition, minimizing stress concentrations and promoting uniform burning, while a secant ogive provides a larger initial burning surface area for a more rapid thrust buildup. Understanding the characteristics, applications, and trade-offs associated with each ogive type is essential for engineers seeking to optimize solid propellant grain designs. Through careful analysis, computational modeling, and experimental validation, engineers can leverage the unique advantages of tangent ogives and secant ogives to create high-performance and reliable solid rocket motors for a wide range of applications. The proper selection between a tangent ogive and secant ogive is a critical consideration that should be carefully evaluated. The impact of using a tangent ogive versus a secant ogive on motor performance and structural integrity cannot be overstated. Choosing between a tangent ogive and a secant ogive requires a deep understanding of the specific mission requirements.